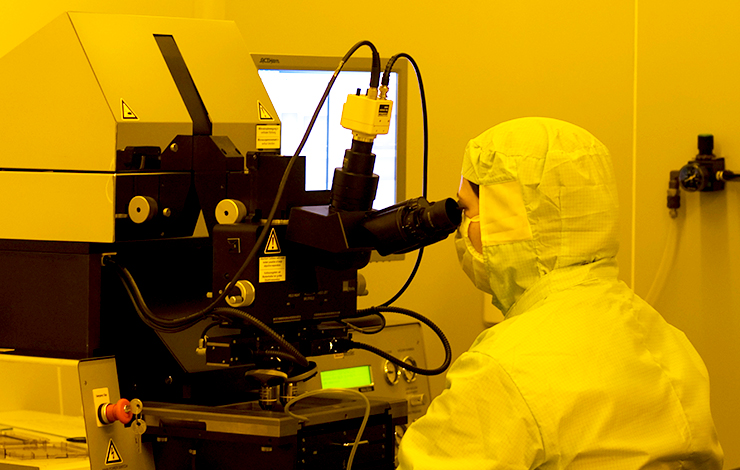

Micro Compunder MC 5 - Xplorer

Location: Fun Paper Lab

Responsible: Rui Igreja

Description:

Xplore developed a twin screw micro compounder with a capacity of just a few grams of material. This micro compounder, which is the smallest in the world, is a unique asset for the development of new material compound formulations. It will improve your R&D by delivering reliable, reproducible and fast test results. A full fledged material processing extruder on a laboratory bench or in your fume hood.

The MC 5 can process batch volumes up to 5 ml. As an option the compounder houses the unique Vari-Batch concept, which gives you the opportunity to select your batch volume between 2 and 5 ml.

Specifications:

• Abrasion resistant barrel (hardness 64 HRC), coating hardness 2000 Vickers

• Barrel and screws chemically resistant between pH 0 – 14

• Vari-Batch™ option for 2 or 5 ml batch size

• Vertical barrel, position (fluid-tight)

• Heated by 8 thermo cartridges and controlled by 7 thermo couples (temperature gradient possible)

• Temperature control: in the melt and 2x3 barrel heating zones

• Detachable conical screws, fully intermeshing (Hardness 54 HRC), coating hardness: 1000 Vickers

• Maximum operating temperature: 450 °C

• Fast and easy to clean with dedicated cleaning cycle

• Heating time (from 20 to 240 °C): 10 min

• Cooling time (from 240 to 80 °C): with cooling water in less than 10 min, with air in less than 35 min

• Acquisition of rheological data (screw torque in melt, melt viscosity, shear rate and shear stress)

• Maximum vertical force: 5 kN - Pressure 200 bar

• Screw speed: continuously variable 1 - 400 RPM

• Front hopper volume: 5 ml, optional water cooled top hopper

• Main drive: DC controlled, 550 Watt-Computer control via: USB port

• Maximum torque: 6 Nm per screw

• Overall dimensions (h x b x d): 83 x 70 x 40 cm

• Weight: 95 kg