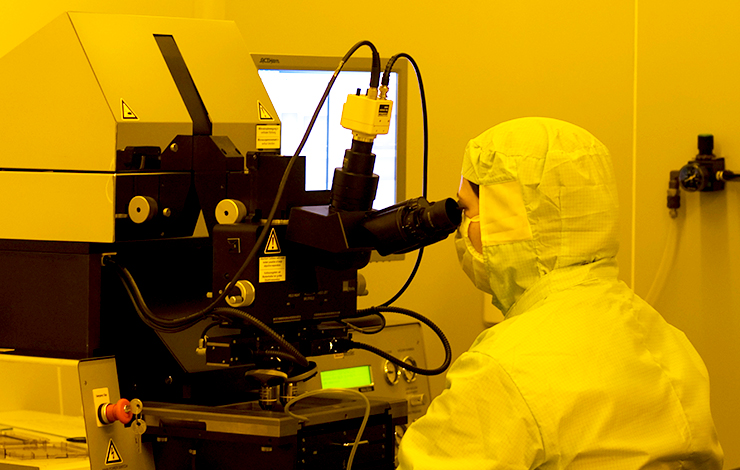

Flexiproof 100UV printer

Location: Fun Paper Lab

Responsible: Cristina Gaspar

Responsible: Cristina Gaspar

Description:

The FlexiProof 100 offers a high speed, operator-friendly machine for the production of proofs using water, solvent or UV flexographic inks. It is an essential tool for all those involved in the manufacture and use of flexo inks. Ideal for quality control testing to ensure consistency of performance of inks and substrates over time, presentation samples, printability of substrates, R&D including product and commercial viability, and computer colour matching data.

The Flexiproof 100 with UV will enable users to accurately simulate UV printing for all prepress applications, from computer colour matching to customer samples and quality control, and from R&D to printability testing, etc. and address printability problems such as pinholing, adhesion, absorption, gloss, shrinkage, wetting, etc.

Specifications:

▪ Quick change, ceramic or steel anilox

▪ Swing in doctor blade with safety cover: Hardened steel stepped edge 92x12x0.15mm

▪ Printing speed: Variable 20 ➝99m/min

▪ Ink types: Solvent based, water based, UV

▪ Single sheet or multiple sheet

▪ PLC controlled

▪ Use any flexible substrate: Flexible paper, board, film and foil

▪ Substrate size: 297x105mm –half A4

▪ Print area up to 240x75 mm

▪ Simple to use and easy to clean

▪ 1.14mm plus 0.5mm, cushion mount photopolymer plate

▪ 4 standard ceramic anilox rollers, with two engraved bands (3-4 cm3/m2, 5-6 cm3/m2, 7-8 cm3/m2 , 13-18 cm3/m2)

▪ Roller adjustment: in steps of 4 micron

▪ Bench space: 55cm wide x 45cm deep

▪ Weight: 45kg net –51kg gross

▪ Accessories: Other plate rolls available for different thickness plates

▪ Optional: UV curing unit

o Substrate size: 125mm x 105mm

o Maximum printing area: 90mm x 80mm

o UV lamp details: 200W/cm Peak wavelength: 310-370 Nm

o UV powerpack: 40cm x 40cm x 20cm –25kgs