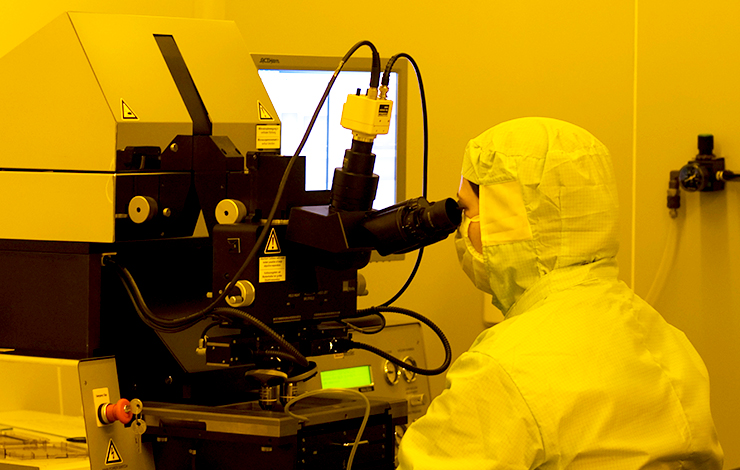

The influence of target erosion grade in the optoelectronic properties of AZO coatings growth by magnetron sputtering

| Title | The influence of target erosion grade in the optoelectronic properties of AZO coatings growth by magnetron sputtering |

| Publication Type | Journal Article |

| Year of Publication | 2016 |

| Authors | Zubizarreta C a, G-Berasategui E a, Ciarsolo I a, Barriga J a, Gaspar D b, Martins R b, Fortunato E b |

| Journal | Applied Surface Science |

| Volume | 380 |

| Pagination | 218-222 |

| ISSN | 01694332 |

| Keywords | Aluminum coatings, Aluminum-doped zinc oxide, Carbon, Ceramic materials, Ceramic target, Coatings, Erosion, Grading, Green manufacturing technique, Hardening, Light emitting diodes, Magnetron sputtering, Manufacture, Optical films, Optoelectronic applications, Optoelectronic devices, Optoelectronic properties, Sputtering, Target erosion, Tin oxides, Transparent conductors, Visible spectral regions, Yarn, Zinc coatings |

| Abstract | Aluminum-doped zinc oxide (AZO) transparent conductor coating has emerged as promising substitute to tin-doped indium oxide (ITO) as electrode in optoelectronic applications such as photovoltaics or light emitting diodes (LEDs). Besides its high transmission in the visible spectral region and low resistivity, AZO presents a main advantage over other candidates such as graphene, carbon nanotubes or silver nanowires; it can be deposited using the technology industrially implemented to manufacture ITO layers, the magnetron sputtering (MS). This is a productive, reliable and green manufacturing technique. But to guarantee the robustness, reproducibility and reliability of the process there are still some issues to be addressed, such as the effect and control of the target state. In this paper a thorough study of the influence of the target erosion grade in developed coatings has been performed. AZO films have been deposited from a ceramic target by RF MS. Structure, optical transmittance and electrical properties of the produced coatings have been analyzed as function of the target erosion grade. No noticeable differences have been found neither in optoelectronic properties nor in the structure of the coatings, indicating that the RF MS is a stable and consistent process through the whole life of the target. © 2016 Elsevier B.V. |

| URL | https://www.scopus.com/inward/record.uri?eid=2-s2.0-84956679889&doi=10.1016%2fj.apsusc.2016.01.147&partnerID=40&md5=6affb1aabea42002deaf7dfedb27f5cc |

| DOI | 10.1016/j.apsusc.2016.01.147 |